Understanding Termite Damage in Indian Homes

Termites cause an estimated ₹50 billion in property damage annually across India, with humid coastal regions and monsoon-prone areas being particularly vulnerable. These pests silently compromise structural integrity by feeding on cellulose-based materials, often going unnoticed until significant damage occurs. Common signs include hollow-sounding wood, mud tubes on walls, and crumbling timber.

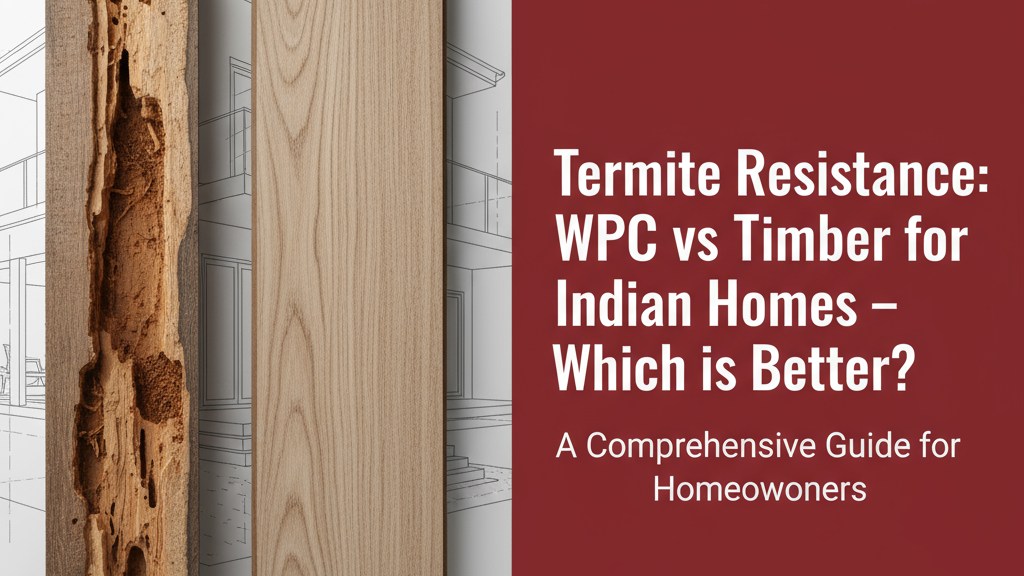

What Makes Timber Vulnerable to Termites?

Traditional timber contains three elements that attract termites:

- Natural cellulose: The primary food source for subterranean and drywood termite species

- Moisture retention: Swelling during monsoons creates micro-cracks that allow termite entry

- Organic imperfections: Knots and grain variations create weak points for infestation

Even chemically treated timber requires reapplications every 3-5 years in high-humidity states like Kerala or West Bengal, as monsoon rains gradually leach out preservatives.

Why WPC is Naturally Termite-Resistant

Wood Plastic Composite (WPC) combines polymer matrices with wood fibres to create a material that termites cannot digest. Key advantages include:

| Feature | Benefit |

|---|---|

| Polymer encapsulation | Seals wood fibres within moisture-proof plastic |

| Inorganic composition | Eliminates cellulose food source |

| Dense structure | Prevents termite mandibles from gaining purchase |

Independent testing shows WPC maintains zero termite damage even after 10+ years in tropical conditions, outperforming most pressure-treated woods.

Comparing Termite Resistance: WPC vs Timber

| Material | Termite Resistance | Humidity Tolerance | Typical Lifespan |

|---|---|---|---|

| Natural Timber | None (requires treatment) | Moderate (swells above 65% RH) | 5-15 years |

| Pressure-Treated Wood | Moderate (chemical-dependent) | High (but chemicals leach) | 8-20 years |

| WPC | Inherent (no treatment needed) | Excellent (no moisture absorption) | 25+ years |

Long-Term Durability Considerations

Beyond termite resistance, WPC offers structural advantages for Indian climates:

- Thermal stability: Expands/contracts 50% less than timber in temperature swings from 5°C to 45°C

- UV resistance: Composite formulations prevent fading better than painted wood

- Load bearing: Higher density (1.1-1.3 g/cm³) maintains rigidity in high-wind areas

Timber requires more frequent inspections for hidden termite damage that may compromise load-bearing capacity over time.

Maintenance Requirements for Each Material

Timber maintenance cycle:

- Annual visual inspections for frass (termite droppings)

- Biennial chemical treatments in humid zones

- Quarterly cleaning/polishing to maintain protective coatings

WPC maintenance cycle:

- Occasional washing with mild detergent

- No sealing or chemical treatments required

Field studies in Mumbai show WPC requires 85% less maintenance time compared to treated timber over a 10-year period.

Cost Implications Over Time

While WPC carries a 15-25% higher initial cost than premium timber, lifecycle costs favour composites:

- Eliminates: Chemical treatment costs (₹150-300/sq.ft every 3 years)

- Reduces: Replacement costs from termite damage (average ₹700/sq.ft)

- Minimises: Labour for ongoing maintenance

Total cost of ownership typically becomes favourable for WPC within 7-10 years in termite-prone regions.

Making the Right Choice for Your Indian Home

Consider these factors when selecting between materials:

- Climate: WPC outperforms in humidity above 70% or rainfall over 2,000mm annually

- Usage: Critical structural elements benefit most from WPC’s consistency

- Aesthetics: Modern WPC textures convincingly mimic wood grains

For heritage properties requiring authentic wood, specify boron-treated timber with stainless steel termite shields – though this increases costs by 40-60% versus standard WPC installations.