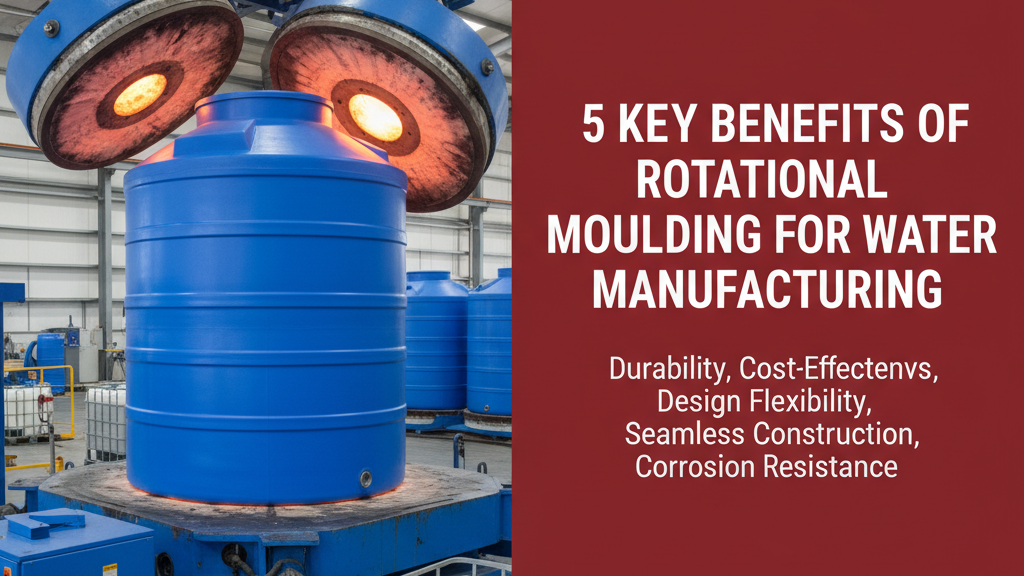

Introduction to Rotational Moulding

Rotational moulding (or rotomoulding) is a specialised manufacturing process where powdered plastic resin is heated and rotated inside a mould to create seamless, hollow products. This method has revolutionised water tank production by offering unique advantages over traditional fabrication techniques like blow moulding or welded steel construction.

Why Rotational Moulding Excels for Water Tanks

Unlike other plastic forming methods, rotomoulding produces uniform wall thickness and eliminates weak points – critical for water storage applications. The slow rotation at controlled temperatures (typically 200–400°C) allows precise material distribution, making it ideal for large-capacity tanks (1,000–20,000 litres) commonly used in Indian homes, agriculture, and industry.

Seamless, Leak-Proof Construction

Rotomoulded water tanks have no welded joints or mechanical fasteners that could fail over time. The one-piece construction:

- Prevents leaks at seams – a common issue with sectional steel or fibreglass tanks

- Eliminates corrosion points found in metal tanks

- Withstands hydraulic pressure better than blow-moulded alternatives

This integrity is particularly valuable in monsoon climates where ground movement and thermal expansion test tank durability.

Exceptional Durability & Weather Resistance

High-quality rotomoulded polyethylene (PE) tanks offer:

- UV stabilisation for 10+ years of sunlight exposure without brittleness

- Operating range from -40°C to 60°C – suitable for Indian temperature extremes

- Chemical resistance to algae, fertilisers, and mild acidic/alkaline water

- Impact resistance 2-3× higher than equivalent PVC tanks

Many ISI-certified rotomoulded tanks carry 5–10 year warranties against material defects.

Cost-Effective Production for Large Tanks

Rotomoulding becomes economically advantageous for tanks above 500 litres due to:

- Lower tooling costs compared to injection moulding

- Minimal material waste (excess powder can be reused)

- Ability to produce thick-walled tanks without secondary processes

- Reduced labour costs versus welded steel tank fabrication

The process also allows in-mould colouring, eliminating post-production painting expenses.

Design Flexibility & Customisation Options

Manufacturers can easily adapt rotomoulded tanks to specific needs:

- Integrated fittings (outlets, overflows, inspection ports)

- Reinforcement ribs for structural support

- Custom shapes (rectangular, conical bottom, slimline designs)

- Stackable or modular configurations

- Branding embossed directly into the plastic

This versatility helps address space constraints in urban installations or specialised industrial requirements.

Environmentally Friendly Manufacturing Process

Rotomoulding compares favourably to other tank production methods in sustainability:

- Energy efficient – no high-pressure injection systems required

- Clean process with negligible volatile organic compound (VOC) emissions

- Polyethylene is 100% recyclable (LDPE/HDPE resin codes 4/2)

- Long product lifespan reduces replacement frequency

Some manufacturers incorporate recycled PE content without compromising tank integrity.

Comparing Rotational Moulding to Other Methods

| Feature | Rotomoulding | Blow Moulding | Welded Steel |

|---|---|---|---|

| Max. Capacity | 20,000+ litres | 5,000 litres | Unlimited |

| Wall Thickness | 6–25mm (uniform) | 2–8mm (variable) | 1–6mm (welds vary) |

| Weather Resistance | Excellent | Good | Requires coating |

| Custom Shapes | High flexibility | Limited | High labour cost |

Choosing the Right Rotomoulded Water Tank

Key selection criteria for Indian conditions:

- Material Grade: Food-grade PE for potable water, UV-stabilised black for outdoor use

- Certifications: ISI Mark (IS 12701:2018), WRAS, or FDA compliance if applicable

- Design Features: Insect-proof lids, debris filters, and anti-vortex outlets improve hygiene

- Installation: Flat base tanks require proper bedding; consider pedestal tanks for uneven ground

For industrial use, verify chemical compatibility with stored liquids.

Conclusion: The Future of Water Tank Production

Rotational moulding continues to dominate water